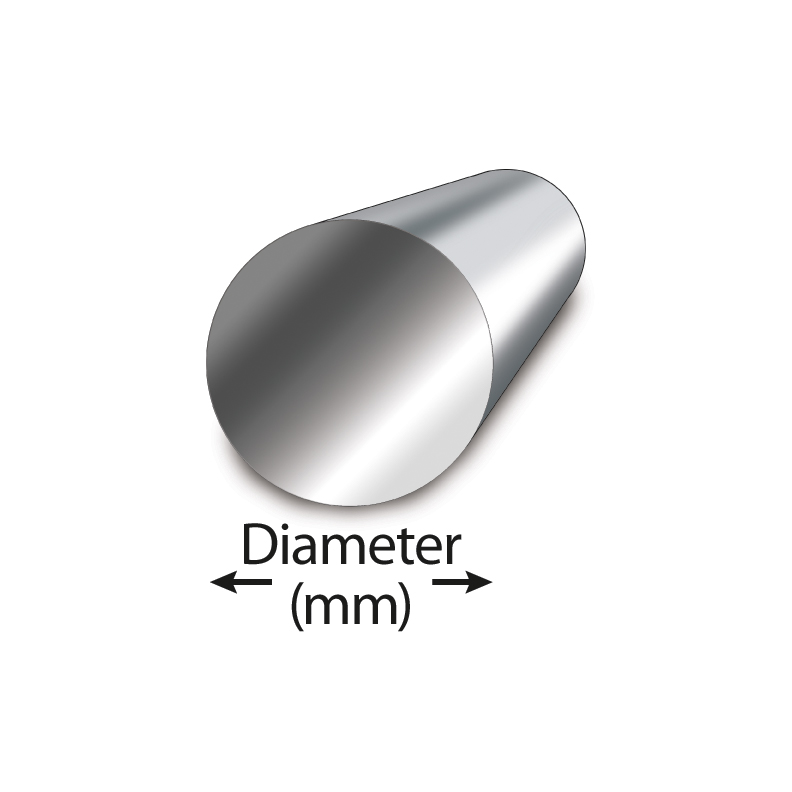

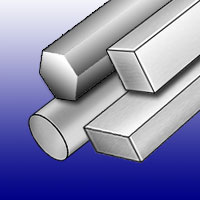

C1018 Cold Finished Round, aka CRS Round or Cold Roll Round Bar is a steel product with closer dimensional accuracy, tolerances, and smoother surface finish than hot rolled barC1018 Cold Finish Round is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bendingSteel Grade AISI C1018 AISI C1018 This grade is produced in an electric arc or basic oxygen furnace and contains the greatest ductility of all carbon steel grades stocked in service centers Stocked in cold finished bars in a variety of shapes and sizes, its relatively low carbon, manganese, phosphorus and sulfur content make it a naturalIn this regard, what is 1018 steel made of?

Aisi 1018 Sheet

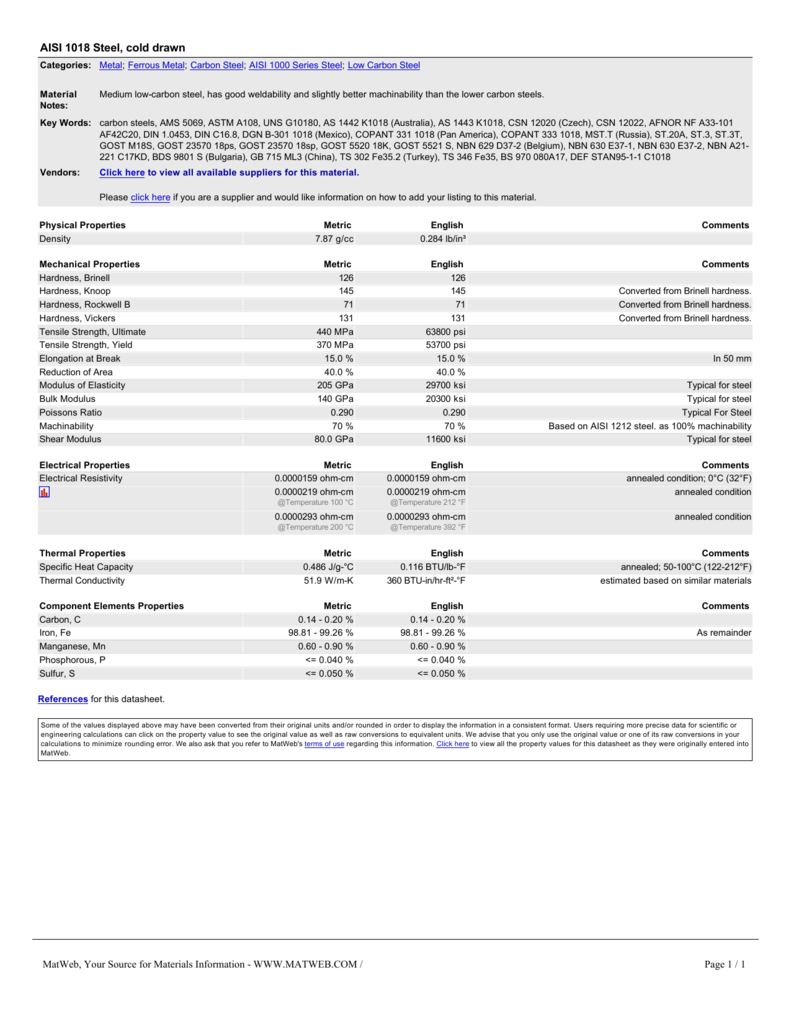

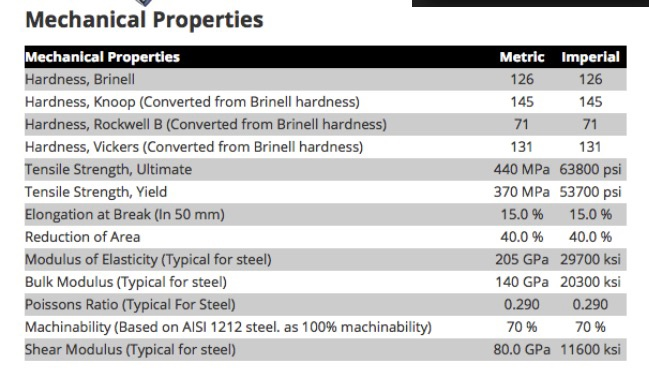

C1018 steel mechanical properties

C1018 steel mechanical properties-1018 cold finish carbon steel is a general purpose, low carbon steel with a higher manganese content that other low carbon grades The higher manganese content allows 1018 to achieve a harder and more uniform case It also possesses greater mechanical properties and machining than similar low carbon grades Typical uses include parts C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case Most 1018 is produced by cold drawing

Sae Aisi 10 Steel Properties C10 Carbon Steel Yield Strength Equivalent

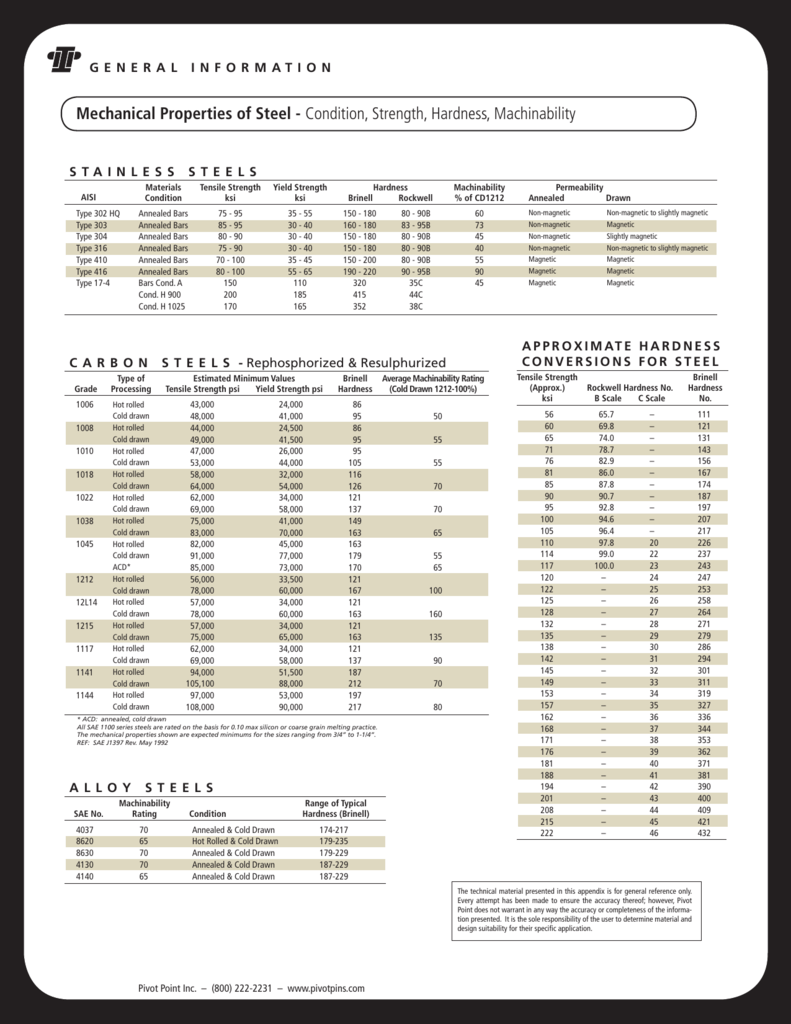

Mechanical Properties of Steel Condition, Strength, Hardness, Machinability Stainless Steels AISI Type 302 HQ Type 303 Type 304 Type 316 Type 410 Type 416 Type 174 Materials Condition Annealed Bars Annealed Bars Annealed Bars Annealed Bars Annealed Bars Annealed Bars Bars Cond A Cond H 900 Cond H 1025 Tensile Strength ksi 75C1018 Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 Cold Rolled C1018 is better steel for carburized parts, since it produces a harder and more uniform case Due to size limitations of the cold drawing process, largeTypical for steel Machinability 70 % 70 % Based on AISI 1212 steel = 100% Shear Modulus 780 GPa ksi Estimated from elastic modulus Electrical Properties Metric English Comments;

Chemically, it is very similar to A36 Hot Rolled steel, but the cold rolling process creates a better surface finish and better properties Typically used in pins, rods, shafts, spindles, and sprockets Common Trade Names UNS G, AISI 1018, C1018, Marshallcrat Other Resources Safety Data Sheet Weight Calculator Mill Test ReportsMechanical properties of structural steel at elevated temperatures and after cooling down are summarized Subsequently, following a proper classification the test data recordings are comprehensively illustrated in a graphical form and compared with the existed design codes FiHardness (HB) 197 25 carburized at 925°C, cooled, reheated to 775°C, water quenched, tempered at 175°C, core properties (round bar (1932 mm)) more

AISI 304 () Stainless Steel AISI 316 Stainless Steel Specification and Datasheet ASTM A1018 ASTM A108 Carbon and Alloy Steel Bars ASTM 79 Stainless Steel ASTM A53 Carbon Steel Pipes ASTM A564 Stainless Steel Age Hardened Advanced High Strength Steel Nomenclature, Grades, and Applications Alloy Steel Properties, ProcessingThe Carbon Steel AISI 1018 / AISI 10 Sheet Plate is the steel plate certified with AISI having the grade 1018 and 10 There is a higher range of demand and uses for the carbon steel sheet plates They are providing great attributes and aspects in the application of industrial purposesAISI 1018 mild/low carbon steel offers a good balance of toughness, strength and ductility AISI 1018 hot rolled steel has significant mechanical properties, improved machining characteristics and has a high Brinell hardness measure Specific manufacturing controls are used for surface preparation, chemical composition, rolling and heating

Important Machining Factors Of Carbon Steels Production Machining

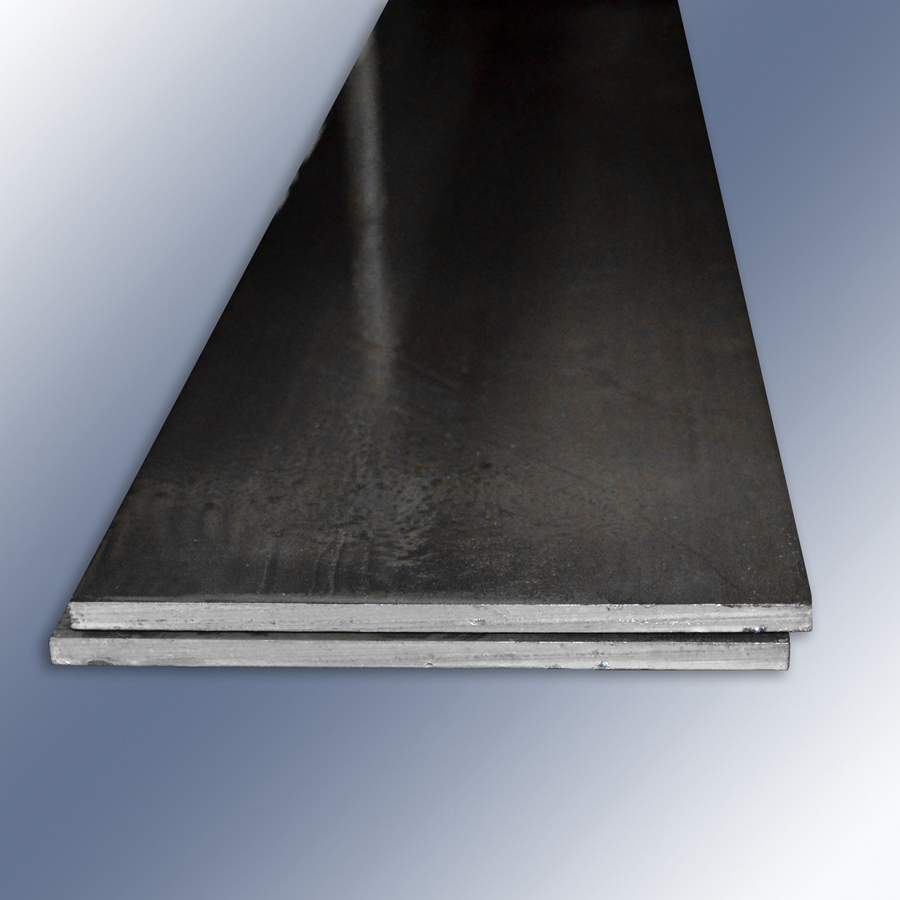

C1018 Cold Finish Flat Bar Steel Finished Product

C1018 Cold Finished Flat, aka CRS Flat or Cold Roll Flat Bar is a steel product with closer dimensional accuracy, tolerances, and smoother surface finish than hot rolled barC1018 Cold Finish Flat is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bending AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR, and has good The bottomline is that the chemistry of AISI 1018 alone does not ensure the mechanical properties are the same as ASTM A108 You can not substitute an AISI steel for a steel that meets an ASTM specification To do so can have unexpected ramifications You can be in violation of the applicable welding standard or contract and it can endanger

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Astm 108 1 25 Thickness 1 5 Width 72 Length Onlinemetals Industrial Scientific

Sae Aisi 10 Steel Properties C10 Carbon Steel Yield Strength Equivalent

AISI 1018 Steel, cold drawn Key Words carbon steels, AMS 5069, ASTM A108, UNS G, AS 1442 K1018 (Australia), AS 1443 K1018, CSN 1 (Czech), CSN 122, AFNOR1018 Cold Roll Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical propertiesA Low Carbon Steel also known as DIN ,JIS SWRCH18A ,ASTM Grade 1018 ,UNS Gwith Mechanical, thermal and chemical properties Datasheet Download

Sae 1018

Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions Sciencedirect

Manufacturer of C1018 STEELCOLD ROLLED FLAT BAR available in a number of sizes to suit your application needs, request a quote or place an order with Metal Supermarkets today In addition to improvement of mechanical properties, the cold rolling produces steel plate/sheet of the desired physical dimensions Steel may be annealed subsequentAISI C1018 (1018 CRS) steel has good weldability, surface curing quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, plastic strength, torsional strength, surface hardness and wear resistance, but reduces plasticity ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR andASTM A108 1018 CW ASTM A108 Introduction As experienced ASTM A108 1018 CW ASTM A108 supplier, we can not only provide clients with quantity guaranteed ASTM products, but also offer good price and equipped with complete after sales service Besides, there are also a series of added value service, such as

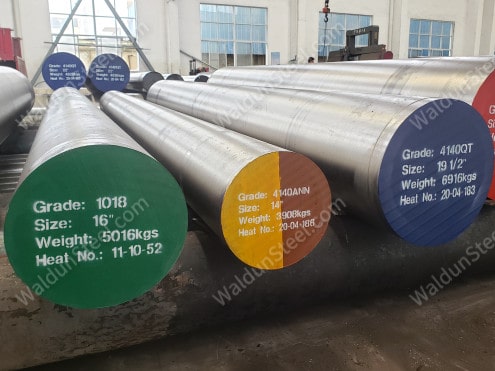

Cold Rolled 1018 Steel Round Bar Cold Rolled Steel Bar Cold Rolled Steel Steel

Metalsdepot 1018 Cold Finish Steel Round Bar

Electrical Resistivity ohmcm @Temperature 0000 °C ohmcm @Temperature 3 °F annealed condition ohmcmIt is usually used as carburized steel Since most of the 1018 carbon steel is produced by cold drawing, this cold rolled steel is called C1018 (1018 cold rolled steel) AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higherC1018 Cold Finish Flat Bar is a low carbon general purpose steel It is one of the most abundantly available metal grades C1018 Cold Finish Flat, is a rolled steel product with close dimensional accuracy, smooth surface finish, and increased mechanical properties and machinability This metal can easily be formed, machined and welded

China Cold Drawn Steel Bar 1018 1045 Free Cutting Steel China 1018 Steel 1018 Forged Steel

Aisi 1018 Carbon Steel Waldun Steel

Provided with higher mechanical properties, AISI 1018 cold rolled carbon steel also includes improved machining characteristics and Brinell hardness Specific manufacturing controls are used for c1018 steel surface preparation, chemical composition, rolling and heating processesSAE 1018 carbon steel is a free machining grade that is the most commonly available grade around the world Although its mechanical properties are not very unique, it still can be easily formed, machined, welded and fabricated Grade Application SAE 1018 carbon steel is commonly used in high volume screw machine parts applicationsIt is usually used as carburized steel Since most of the 1018 carbon steel is produced by cold drawing, this cold rolled steel is called C1018 (1018 cold rolled steel) AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

Acero Laminado En Frio Barra Plana 1018 3 4 X 6 X 36 Ebay

It is usually used as carburized steel Since most of the 1018 carbon steel is produced by cold drawing, this cold rolled steel is called C1018 (1018 cold rolled steel) AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higherC1018 Cold Finish Round, is a rolled steel product with close dimensional accuracy, smooth surface finish, and increased mechanical properties and machinability C1018 Cold Finish Round is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bendingInformation,mechanical properties, physical properties, mechanical properties, heat treatment, and Micro structure, etc It also contains the use of AISI 1018,such as it is commonly used in bars, sheet,plates, steel coils, steel pipes,forged and other materials application Datasheet for Steel Grades Carbon Steel AISI 1018 AISI 1018 Standard

Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions Sciencedirect

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Cold Finish Astm 108 0 125 Thickness 0 25 Width 84 Length Onlinemetals Industrial Scientific

Speedy Metals items C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical propertiesWith higher manganese, C1018 is better steel for carburized parts since it produces a harder and more uniform case It also has higher mechanical properties and better machinability due to the cold drawing process Most C1018 is produced by cold drawing In this process, oversized hot rolled bars, which have been cleaned of scale, are drawnGet access to over 8,000 types, shapes and grades of metal We carry hot and cold rolled steel, aluminum, stainless steel and much more

Aisi 1018 Carbon Steel Round Bar Hot Rolled Sae 1018 Rod Flat Bar

1018 Cold Finished Carbon Steel Bar Alro Steel

Carbon steel is a steel with carbon content from about 005 up to 38 per cent by weight The definition of carbon steel from the American Iron and Steel Institute (AISI) states no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloyingASTM A572 Grade 50 Steel ASTM A572 grade 50 steel is a lowalloy highstrength structural steel with a yield strength of 50 ksi (345 MPa) and a tensile strength of 65 ksi (450 MPa) It has better mechanical properties than ASTM A36 steel Both SAEAISI 1018 steel and SAEAISI 4140 steel are iron alloys They have a very high 98% of their average alloy composition in common There are 31 material properties with values for both materials Properties with values for just one material (1, in this case) are not shown For each property being compared, the top bar is SAEAISI 1018

Mechanical Properties Of Aisi 1018 Steel Download Table

World Steel Grades Equivalent Us Astm Aisi Sae European En Japan Jis Standard Page 2

Known for its good mix of strength, ductility and hardness, 1018 steel is a mild, lowcarbon steelThis alloy of steel has a small percentage of manganese to help achieve these properties While other steels can exceed its mechanical properties, 1018 steel is more easily manufactured and machined, reducing its costMechanical Properties (following values are average and are representative) Commercial Drawing Tensile Strength (psi) 3850,000 3646,000 Yield Point (psi) 2330,000 Elongation (% in 2") 3542 3843 Weldability Yes Forming Yes C1018 Cold Finished Bar A low carbon steel with medium manganese content SAEAISI 1018 steel is a carbon (nonalloy) steel formulated for primary forming into wrought products 1018 is the designation in both the SAE and AISI systems for this material G is the UNS number The properties of SAEAISI 1018 steel include two common variations

Aisi 1018 Carbon Steel Round Bar Hot Rolled Sae 1018 Rod Flat Bar

Pdf Microstructure And Mechanical Properties Of Cold Rolled Aisi 1018 Low Carbon Steel

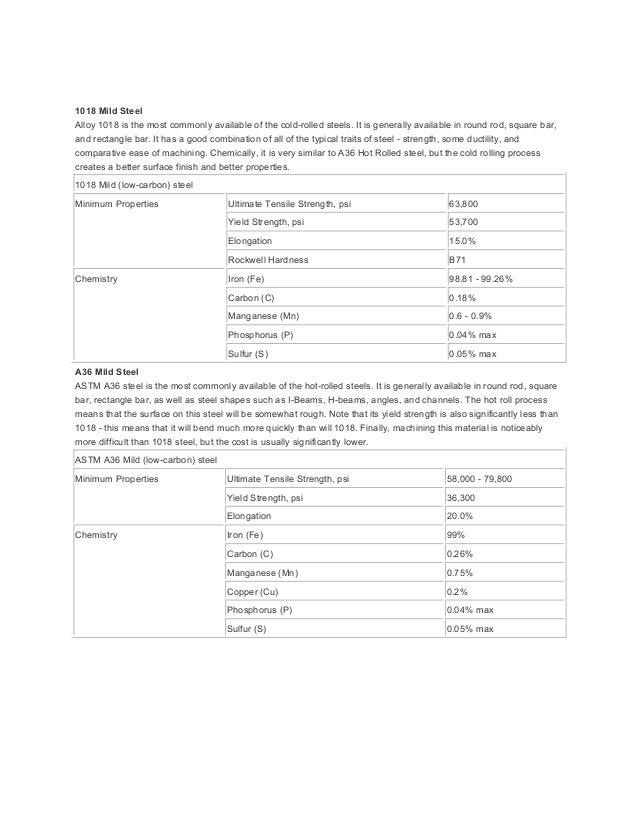

Mechanical properties for SAE 1008 steel are Tensile strength 340 MPa psi, Yield strength (depending on temper) 285 MPa psi, Bulk modulus (typical for steel) 0 GPa ksi, Shear ASTM A36 is the most commonly used mild and hotrolled steel It has excellent welding properties and is suitable for grinding, punching, tapping, drilling and machining processes Yield strength of ASTM A36 is less than that of cold roll C1018, thus enabling ASTM A36 to bend more readily than C1018Both 1018 and 10 steel are frequently purchased steel grades, many questions come up between the differences in 1018 and A36 steel particularly in the chemical makeup and the mechanical properties of the two different steel grades We thought it would be best to provide a comparison for A36 and 1018 steel that outlines those key differences

Aisi 1018 Steel Cold Drawn

Solved A An Aisi 1018 Ductile Hot Rolled Steel Bar Has The Chegg Com

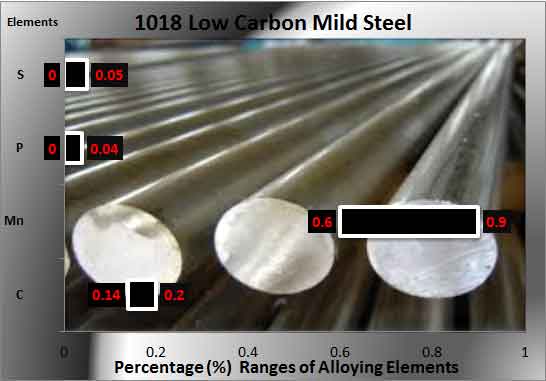

1018 Cold Finished Most cold finished bars are produced by cold drawing oversize hot rolled bars through a die The cold reduction of the bar results in significantly improved mechanical properties, with a smooth surface finish to close tolerances The cold working of the bar likewise improves machinability, usually rated at 76Information,mechanical properties, physical properties, mechanical properties, heat treatment, and Micro structure, etc It also contains the use of 1018,such as it is commonly used in bars, sheet,plates, steel coils, steel pipes,forged and other materials application Datasheet for Steel Grades Carbon Steel 1018 1018 Standard Number ITEMMinimum Properties Rockwell Hardness 1 Iron (Fe) 91 9926% Carbon 018% Manganese (Mn) 06 09% Phosphorus (P) 004% max Chemistry Sulfur (S) 005% max A36 Mild Steel ASTM A36 steel is the most commonly available of the hotrolled steels It is generally available in round rod, square

Pdf Microstructure And Mechanical Properties Of Cold Rolled Aisi 1018 Low Carbon Steel

1018 Steel Grade Guide Metal Supermarkets Youtube

1

Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions Sciencedirect

Carbon Steel 1018 Forging Metal Ministry Inc

Pdf Experimental Investigation Of The Effect Of Vibration On Mechanical Properties Of Aisi 1018 Mild Low Carbon Steel Welded Joint Using Smaw Semantic Scholar

2

Aisi 1018 Steel Carbon Steel 1018 Blacksmiths Depot

1018 Steel Aisi 1018 1 0401 C15 080a15 Waldun Steel

1018 Cold Roll Bearing Quality Alcobra Metals

Mild Steel Properties

Aisi 1018 Astm A108 Grade 1018 Sae 1018 1018 Steel Bar

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

Pdf Experimental Investigation Of The Effect Of Vibration On Mechanical Properties Of Aisi 1018 Mild Low Carbon Steel Welded Joint Using Smaw Semantic Scholar

Steel Grade Aisi C1018 Richmond Steel Canada

Sae 1018 Carbon Steel Sae 1018 Forging Sae 1018 Flat Saaj Steel

Doc Astm A36 Mild Asif Ali Academia Edu

Mechanical Properties Of Aisi 1018 Steel Download Table

7 Things To Consider When Choosing A Carbon Steel Grade

Aisi 1045 Carbon Steel

In Stock Wholesale Pickled Oiled A 36 Steel Angle

Magnetic Permeability 1008 Vs 1018 Magnetic Engineering Eng Tips

.jpg)

Aisi 1018 Mild Low Carbon Steel

Aisi 1018 Sheet Suppliers In India Aisi 1018 Plate And Sheet Metal

Pdf Experimental Investigation Of The Effect Of Vibration On Mechanical Properties Of Aisi 1018 Mild Low Carbon Steel Welded Joint Using Smaw Semantic Scholar

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

Pdf Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions

Astm A36 Mildlow Carbon Steel Pdf Steel Strength Of Materials

1018 Cold Drawn Steel Bar Stock Capital Steel Wire

Carbon Steel Aisi 1018 Angle Aisi 1018 Carbon Steel C Channel Carbon Steel Aisi 1018 Beam Aisi 1018 Carbon Steel Chain Manufacturers Suppliers

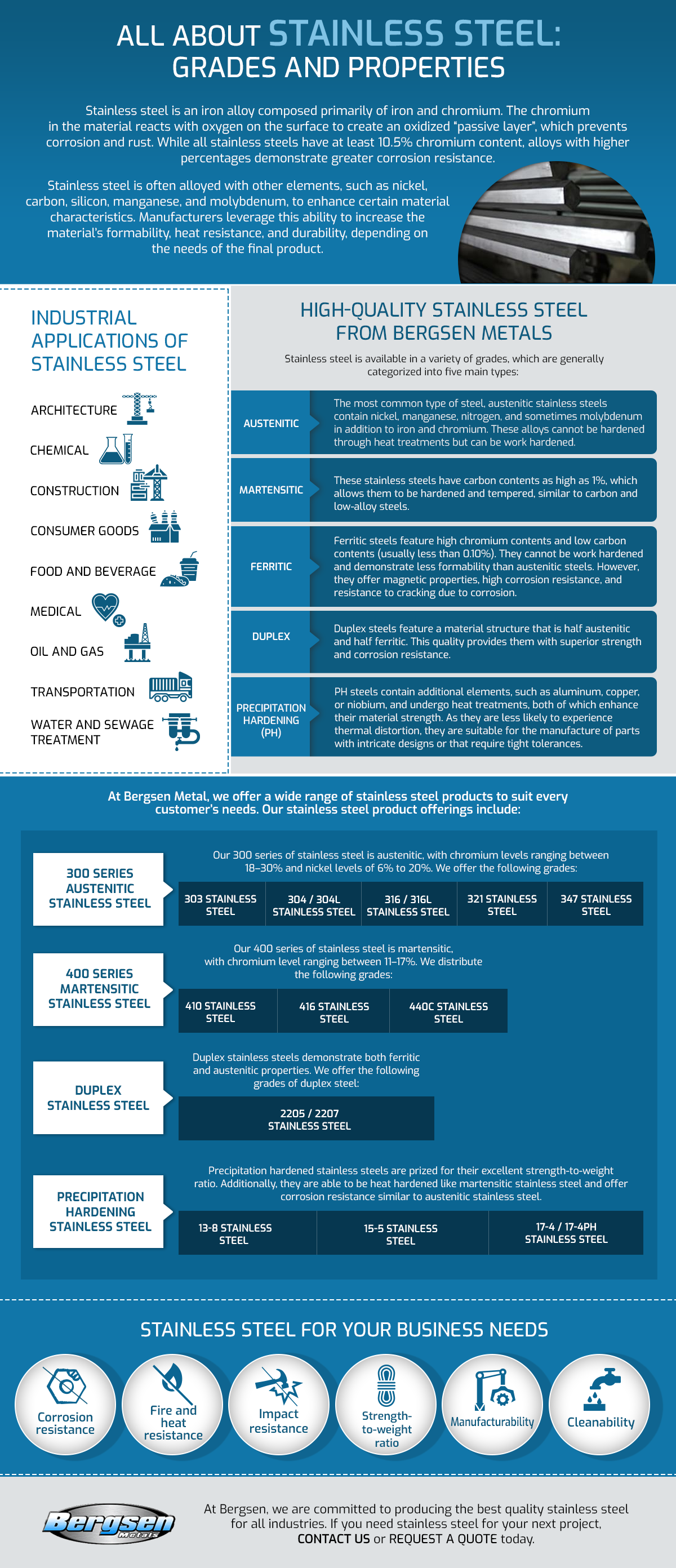

Stainless Steel Grades And Properties Bergsen Metal

Ladhani Metal Corporation 91 In Mumbai India

Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions Sciencedirect

1018 Cold Rolled Steel Square Bar Coremark Metals

Aisi 1018 Steel Carbon Steel 1018 Blacksmiths Depot

Aisi 1018 Carbon Steel Round Bar Hot Rolled Sae 1018 Rod Flat Bar

Cnc Steel Material Cnc Machining Steel Fictiv

Metric Round Bar 1018 Carbon Steel Shafting Metric Metal

Aisi 1018 Sheet

Which One Is Preferable Aisi 1018 Or Aisi 10 Quora

Carbon Steel Aisi 1018 Round Bars Aisi Sae 1018 Bright Bar Cs Aisi 1018 Forged Bar

C1018 Steel

Aisi 1018 Low Carbon Steel 1018 Polished Cold Drawn Bar Alloy Steel Malaysia Selangor Kuala

Cold Rolled 1018 Steel Square Bar Cold Rolled Steel Bar Cold Rolled Steel Steel

1018 Hot Rolled Steel Carbon Steel Bars 1018 Carbon Steel Bar Alro Steel

2

Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions Sciencedirect

Typical Stress Strain Relationship Curves For Cds Aisi 1018 At Download Scientific Diagram

Aisi 1018 Sheet Suppliers In India Aisi 1018 Plate And Sheet Metal

Solved As Needed Use The 1018 Steel Mechanical Property Chegg Com

Carbon Steel Aisi 1018 Bright Bars Aisi 1018 Cs Round Bar Carbon Steel Aisi 1018 Flat Bars Manufacturer Supplier Stockists

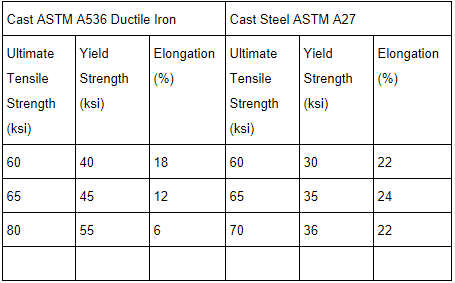

Comparison Of Ductile Iron Vs Steel Penticton Foundry

Heat Treating 1018 Steel Steel Choices

Carbon Steel Aisi 1018 Fasteners Manufacturer Exporter Ubique Alloys Pvt Ltd

Mechanical Properties Of Steel Condition Strength

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

Carbon Steel Wire Cloth Grating Expanded Perforated Sheet Marco Specialty Steel

The Properties Of The Steel Aisi 1018 Download Table

1018 Carbon Steel Coil

Pdf Example Long Laboratory Report Mechanical Properties Of 1018 Steel In Tension Semantic Scholar

Carbon Steel Grades

Astm Sae Aisi 1018 Carbon Steel Chemical Composition Mechanical Properties

Mechanical Properties Of Low Carbon Steel Aisi 1018 11 Download Scientific Diagram

Difference Between A36 Vs 1018 Steel Surprising Answer

China Cold Drawn Steel Bar 1018 1045 Free Cutting Steel China 1018 Steel 1018 Forged Steel

Aisi Astm 1018 En2c Non Alloy Engineering Steel

China Aisi 1018 Cold Drawn Steel Bar Cold Rolled Steel C1018 China Steel Bar Steel Round Bar

A36 Properties Pdf Steel Strength Of Materials

Order 0 125 Mild Steel Round Bar 1018 Cold Finish Online Diameter 1 8

Astm A519 Grade 1018 Steel Tubing And Aisi 1018 Seamless Pipe Supplier

China Aisi Astm 1018 En2c Non Alloy Engineering Steel China 1018 Steel 1018 Forged Steel

2

1018 Carbon Steel Bar 1018 Cold Rolled Steel Bar Cromdane Steel Inc

2

Metalsdepot 1018 Cold Finished Steel Square Bar

2

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

Aisi 1018 Steel As Cold Rolled Quality In American Standard

Things To Consider While Choosing Best Quality Of Carbon Steel By Astec Steel Medium

Cold Rolled Steel Round Bar Coremark Metals

0 件のコメント:

コメントを投稿